3D Laser measurement machine RF096.2D-100/410-305

3D Laser measurement machine RF096.2D-100/410-305

| Parameter | Value | |

| ID measuring range, mm | 100...410 | |

| Rim height range, mm | 70...305 | |

| Measured parameters |

average, maximum and minimum diameter; roundness (all in programmable positions along the workpiece height); height; width and angle of chamfers |

|

| Measurement error, mm | ±0.05 | |

| Light source |

red semiconductor laser, 660 nm wavelength |

|

| Laser safety class | 2М (IEC60825-1) | |

| Interface | Ethernet and PROFINET | |

| Measurement time, s | <20 | |

| Power supply, V | 220 | |

| Weight, kg | 47 | |

Note: Machine parameters can be changed for a specific task.

The work of the machine is based on the principle of 3D laser scanning of object/ objects with subsequent construction of a 3D computer model and determination of geometrical parameters from the model.

The operation of the machine is based on the principle of scanning the inner surface of the hole with a rotating 2D triangulation laser sensor RF627 Series.

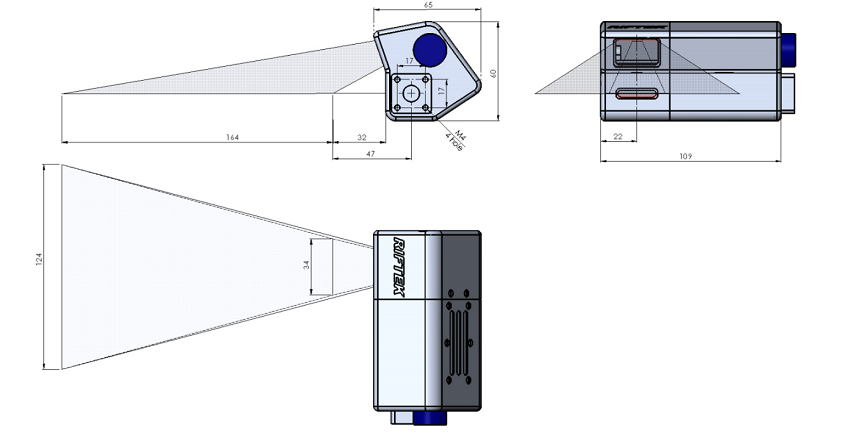

Overall dimensions of the laser sensor:

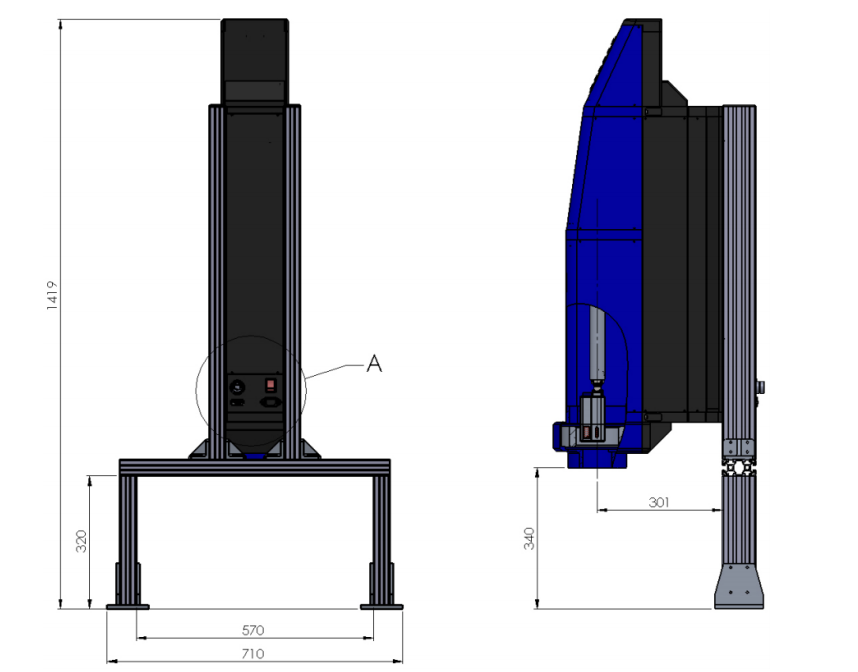

The machine contains a main frame on which the linear movement system, the controller and the interface module are installed. The linear movement system carries the rotation module on which the 2D laser sensor is mounted. On the back of the machine, there are three connectors for connecting power and interfaces, as well as a power button.

The machine operates as follows.

The part to be measured is installed on the same axis with the sensor rotation system. At the command of the external controller, the laser sensor moves into the measured hole. The sensor starts rotating and scans the inner surface of the part. The controller transmits the polar coordinates of the surface (distance from the axis of rotation measured by the sensor and the corresponding angle of rotation) to the computer to calculate the required geometric parameters. The results are transmitted to the external controller via PROFINET.

3D inspection machine RF096.2D-100/410-305

РФ096.2D-Dmin/Dmax-L

| Symbol | Description |

| Dmin/Dmax | ID measuring range, mm |

| L | Measured hole depth, mm |

Example: RF096.2D-100/410-305 - 3D Inspection Machine, ID measuring range - 100...410 mm, measured hole depth - up to 305 mm.

Your message has been sent

Fill out another formSomething went wrong. try again

Fill out another form