Laminated Tubes Geometry Measurement System RF092

Laminated Tubes Geometry Measurement System

| Name of parameter | Value |

| Measured diameters, mm | 13...50 |

| Diameter measurement accuracy, um | ± 10 |

| Foil thickness range, mm | 0,05…0,5 |

| Foil and weld thickness measurement accuracy, um | ± 5 |

| Tube length measurement accuracy, mm | ±0,1 |

| Interface to PC | Ethernet |

| Power supply | 220 V |

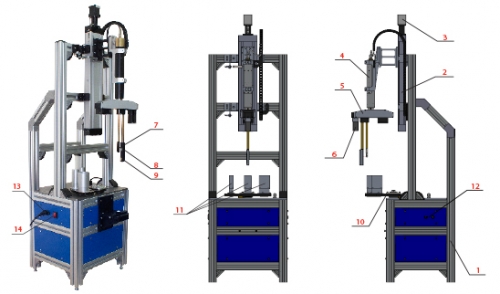

The system contains main frame 1 which carries linear translation stage 2 with stepper motor 3. Translation stage 2 carries rotation module 4 with in-built motor and encoder (not shown). Three-position linear translation module 5 with motor 6 is placed on rotational module The module 5 carries three triangulation laser sensors 7-9. Laser sensor 7 is intended for scanning of tube inner surface, laser sensors 8 and 9 are intended for scanning of tube outer surface. Measurement lines of sensors 7 and 8 are aligned. To eliminate the influence of the sensors on each other under the control of semi-transparent films, sensor 8 contains blue laser and sensor 7 — red one. The system contains rotational table 10, which carries three calibration cylinders 11 for automatic system calibration. Interface connector 12, power supply connector 13 and ON/OFF switch 14 are shown also.

The machine operates as follows:

The tube (not shown) is placed in measurement position under laser sensors by such a way that tube axis coincide with rotation axis of rotational module 4.

To get required accuracy measurement range of laser sensors must not exceed 5 mm, so all the range of tube diameters (20...50 mm) is divided on 3 subranges (20...30, 30...40 and 40...50 mm). Depending on tube diameter the module 5 places sensor into one of three possible control positions (there are three positions of sensors radial shift according to module 4 rotational axis).

The linear translation system 2 lets down laser sensors. During the translation sensor 9 determines the tube edge position (it is a start of tube length measurement) and then sensors 7, 8 determine the same edge.

After registration of tube upper edge the system translates sensors into position of tube shape control (10 mm from the edge).

Module 4 rotates module 5 with sensors. Sensors measure distances to tube inner and outer surfaces. The data are transmitted to PC where foil thickness, weld parameters and tube shape are calculated.

After completing a full revolution the system 2 lets down laser sensors and sensor 9 measures tube length.

Sensors are raised to upper position and measurement cycle repeats for the next tube.

Laminated Tubes Geometry Measurement System

Your message has been sent

Fill out another formSomething went wrong. try again

Fill out another form