Flat Washer (Spacer) Thickness Measurement System RF035 Series

Flat Washer (Spacer) Thickness Measurement System

| Parameter | Value | |

| Thickness measurement range, mm | 0,6...3,5 | |

| Measurement accuracy, μm | ±5 | |

| Spacers diameter, mm | 25,4 | |

| Productivity, pcs/hour | >1000 | |

| Light source |

red semiconductor laser, 660 nm wavelength |

|

| Output power, mW | <1 | |

| Laser safety class | 2 (IEC60825-1) | |

| Interface | Ethernet | |

| Power supply, V | 220 | |

| Environmental resistance: | ||

| Vibration | 20 g / 10…1000 Hz, 6 hours for each of XYZ axes | |

| Shock | 30 g / 6 ms | |

| Permissible ambient light, lx | 30000 | |

| Relative humidity, % | 5-95 (no condensation) | |

| Operating ambient temperature, °С | 0…+45 | |

| Storage temperature, °С | -20…+70 | |

| Dimensions, mm | 442х240х339 | |

| Housing material | aluminum | |

Operation of the system is based on the principle of laser scanning of the spacer surface by two laser sensors located on the opposite sides of the spacer.

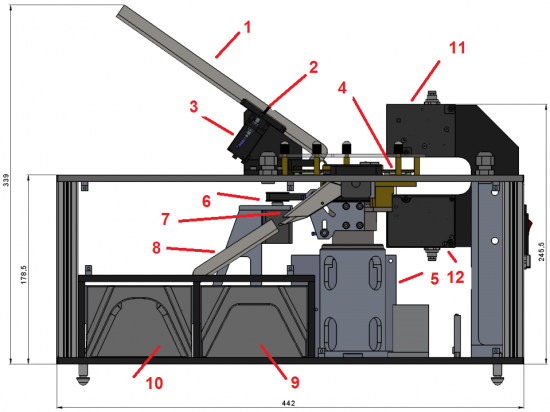

The structure of the system is shown below (the side covers are removed):

The system contains a base, on which the following parts are installed: a tray for spacers (1), dispenser (2) with a drive (3), disc (4) with a drive (5), rotation drive for spacers (6), tray for defective spacers (7), tray for good spacers (8), containers (9) and (10) for collecting the defective and good spacers respectively, laser sensors (11) and (12).

Disc (4) carries two calibration spacers (13) of the known thickness. On the side panel, there is a connector for power supply and a turn-on button (14 and 15), and a connector for connection to PC.

The system operates as follows.

Controlled spacers are manually placed on the tray (1), the dispenser (2) successively throws the spacers onto the rotating disk (4), which moves the spacers in the measuring zone of laser sensors (11) and (12). When the spacer is in the measuring zone, it is rotated by the drive (6), and, as a result, the thickness is measured in a spiral on the spacer surface, which allows to register the extended surface defects. After the measurement, the spacer comes into the tray (7), which tilts and throws it into the container for defective spacers (9), or into the container for good spacers (10).

Flat Washer (Spacer) Thickness Measurement System

Your message has been sent

Fill out another formSomething went wrong. try again

Fill out another form