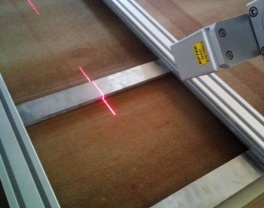

Turn-key solution on the base of 2D laser scanners and point triangulation sensors for continuous contactless measurement of gypsum boards geometrical parameters.

The system for gypsum boards dimensional measurement

- 3DGipsumB

3DGipsumB. The system for gypsum boards dimensional measurement. Specification

| Parameter | Value |

| Measurement object |

Gypsum plasterboards (sheets) with straight, rounded and beveled edges |

| Width range, mm | 400...1400 |

| Thickness range, mm | 2...45 |

| Thickness measurement error, mm | ±0.1 |

| Width measurement error, mm | ±1 |

| Profile measurement error, mm | ±0.1 |

| Range of linear displacement modules, mm | 800 |

| Linear positioning error of laser scanners, mm | ±0.02 |

| Power supply | 220 V, 400 W |

| Computer |

Industrial computer, 19” touch screen (central computer) 17” touch screen (additional terminal) |

| Dimensions of computer consoles, mm | 1509х800х550 (central), 1509х600х550 (additional) |

As the gypsum boards move along the conveyor, they are continuously measured by

the system's sensors.

Information from sensors is processed on a central computer using the supplied

software (hereinafter referred to as the software). If the values of the parameters are outside

of tolerances, a corresponding warning is displayed on the screen of the central computer

and the additional operator terminal.

Structure

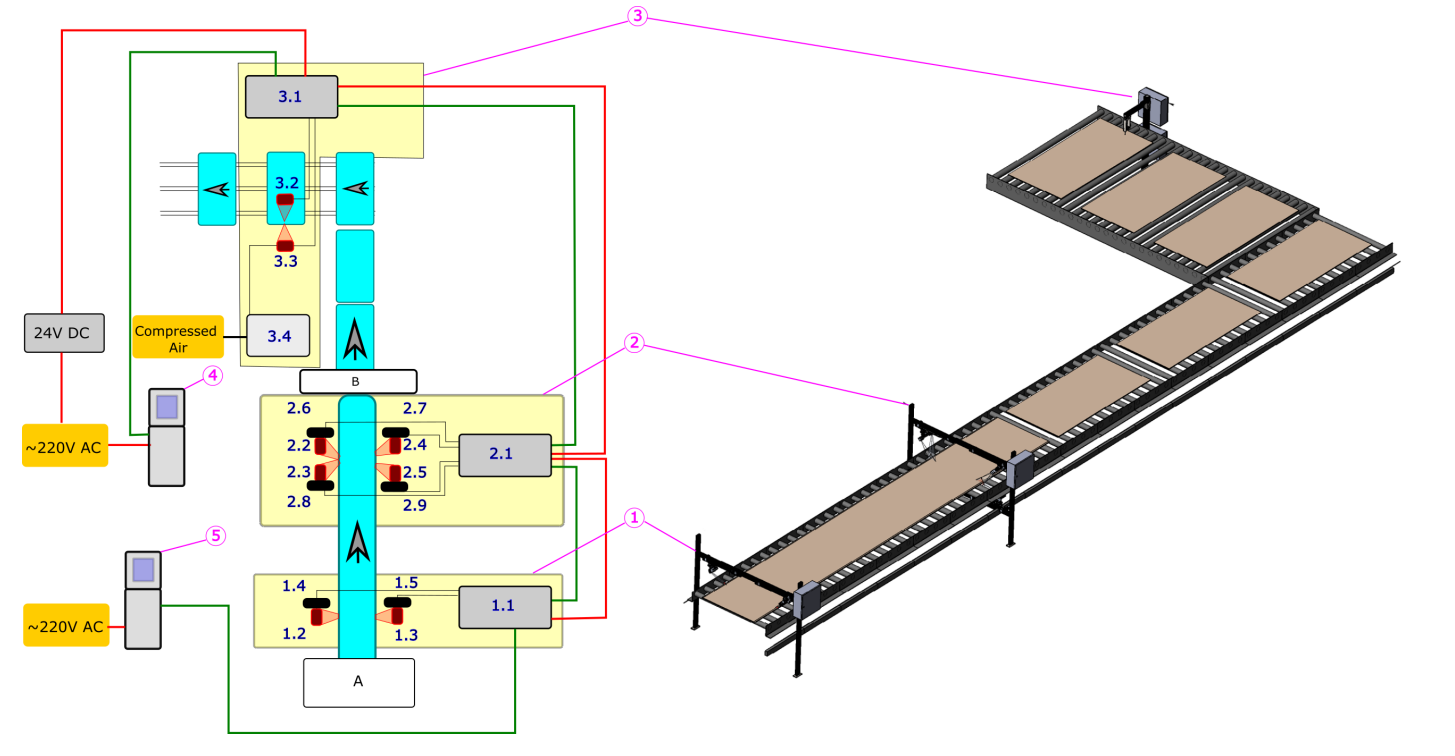

The 3DGypsumB system contains three measuring stations located along the production line.

Figure 1 - Functional block diagram of the 3DGypsumB system

1 – Measuring station #1.

2 – Measuring station #2.

3 – Measuring station #3.

4 – Additional operator terminal.

5 – Central computer.

A – Mixer / molding.

В – Slicing.

Red lines – 24V power supply (generated by the system).

Green lines – Ethernet network of the system.

The system for gypsum boards dimensional measurement. 3DGypsumB Series.

Your message has been sent

Fill out another formSomething went wrong. try again

Fill out another form