Laser Debris Inspection System RF096-Insp

Laser Debris Inspection System RF096-Insp

| Parameter | Value | |

| Inspected grooves diameter range, mm | 35...53 | |

| Minimal size of detected debris, mm | 0,03 (thickness) x 0,1 x 0,1 | |

| Space resolution (points/turnover) | 3200 | |

| Laser sensor linearity, um | ±10 | |

| Inspection time, s | 1,2 | |

| Light source | red semiconductor laser, 660 nm wavelength | |

| Output power, mW | <1 | |

| Laser safety Class | 2 (IEC60825-1) | |

| Laser beam shape | Round | |

| Laser spot size, mm | 0,1 (beginning of the range) - 0,2 (middle of the range) - 0,35 (end of the range) | |

| Output interface | parameterization, profile data and inspection result transfer | Ethernet (UDP) |

| logical (AL) | 0…1 (low level) - power supply (high level), V | |

| Command input (IN) | 0...1 (low level) - 4,5...24 (high level), V | |

| Power supply, V | 9 …24 | |

| Power consumption, W | 3 (standby mode) , 20 (scan mode) | |

| Environment resistance | Enclosure rating | IP67 |

| Vibration | 20g/10…1000Hz, 6 hours, for each of XYZ axes | |

| Shock | 30 g / 6 ms | |

| Operation temperature, °С | -10…+60, (-30…+60 for the sensors with in-built heater), | |

| Permissible ambient light, lx | 30000 | |

| Relative humidity | 5-95% (no condensation) | |

| Storage temperature | -20…+70 , °С | |

| Housing material | aluminum | |

| Weight (without cable) | 1100 gram + magnet holder (280 gram) | |

Operation of the system is based on the scanning of the item surface by binocular triangulation laser sensor.

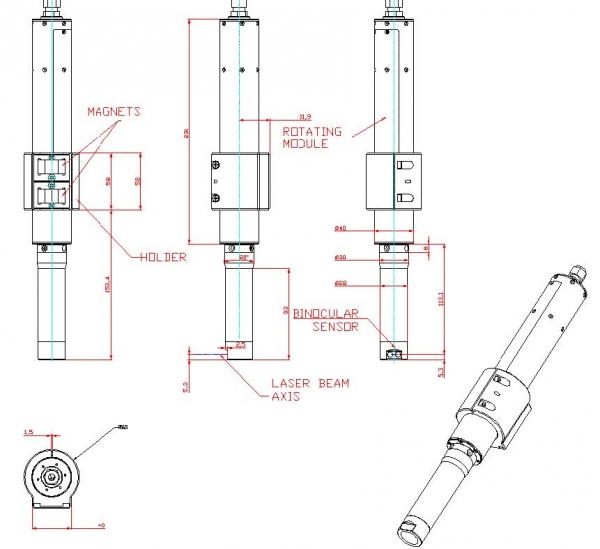

The system contains laser sensor mounted on rotating module (Figure 1.).

Radiation of a semiconductor laser from the sensor is focused onto an item surface.

Radiation reflected by the surface is collected by two input lens of the sensor. The sensor is rotated and scans the surface. Distance to the surface, measured by laser sensor and corresponding angle of rotation form polar coordinates of the surface. In-built signal processor analyzes the surface profile and detects the presence of debris on the surface.

RF096-Insp Laser Debris Inspection System

Your message has been sent

Fill out another formSomething went wrong. try again

Fill out another form